Co-Author

Coming Soon

Underwater Hydroacoustic Textbook

Tij

Vishwakarma

Jaia Robotics, Inc.

Hi, my name's

Tij and

I am a

Mechanical Robotics Engineer

at Jaia Robotics

Inc. I have

a combined experience

of 3+ years,

with a proven

history of professional

and academic excellence,

as highlighted through this

portfolio. Currently, I

am open to new

opportunities across the

United States. Let's

talk!

Underwater Hydroacoustic Textbook

Florida Tech

Catania Product Development

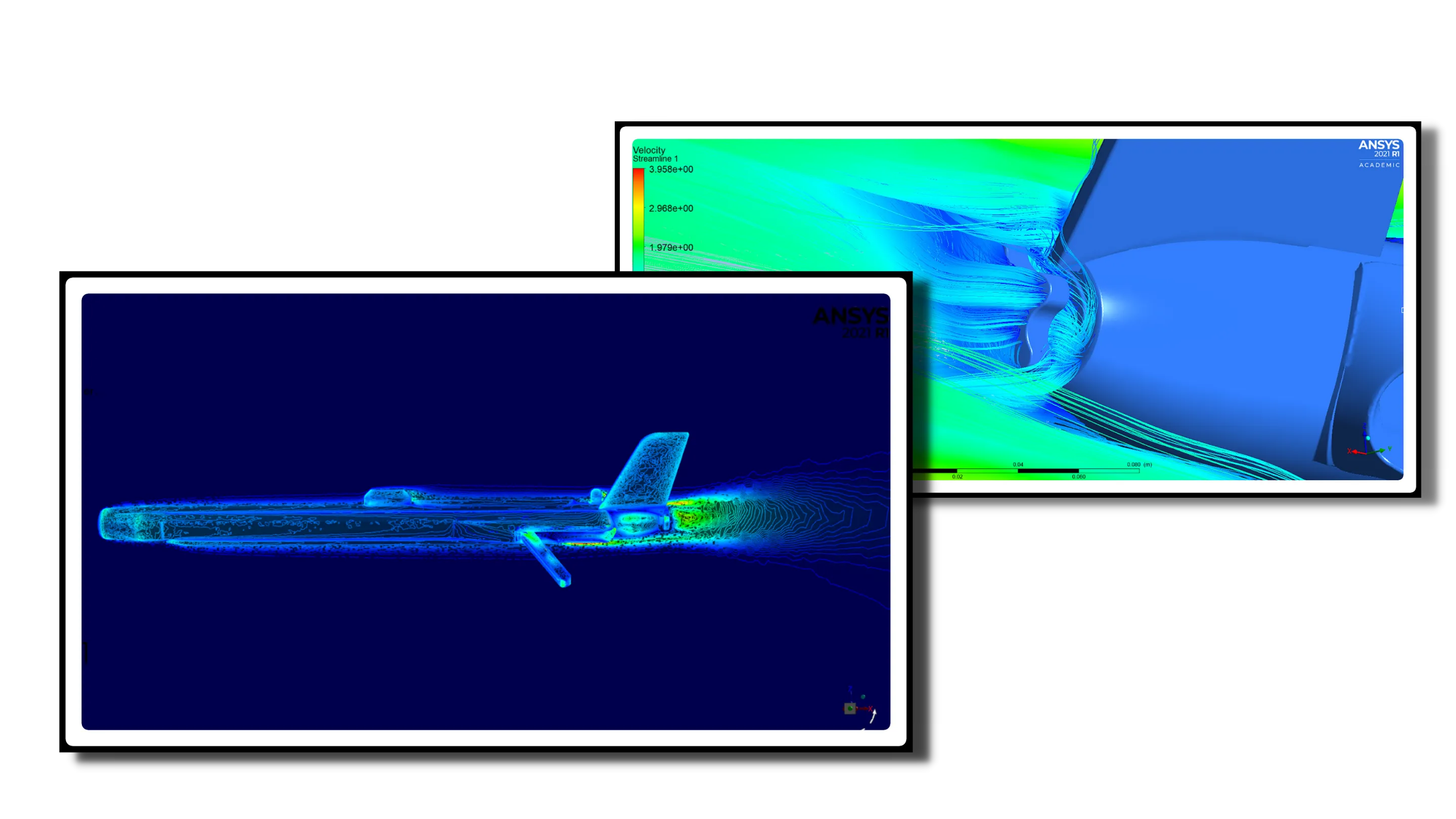

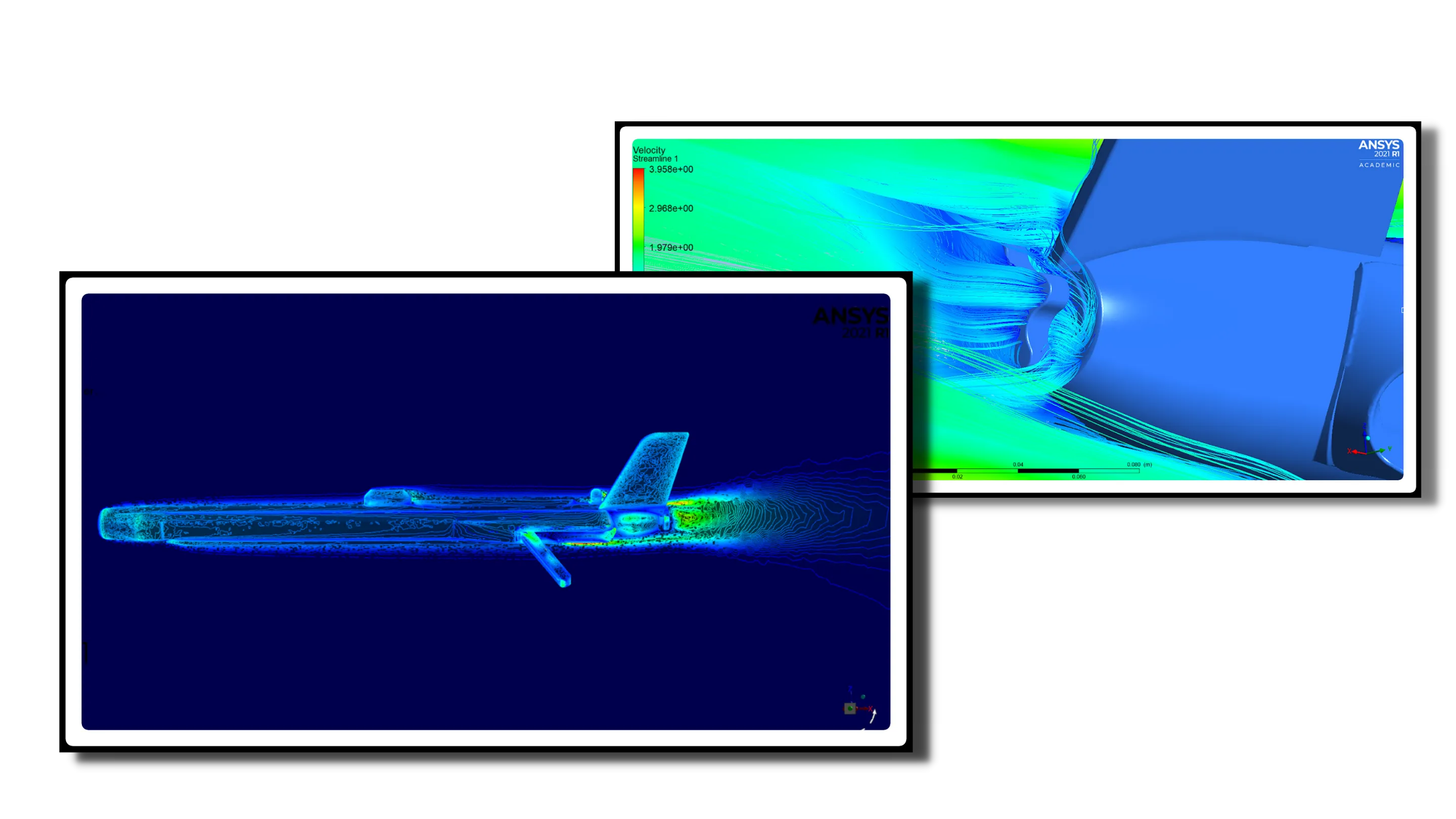

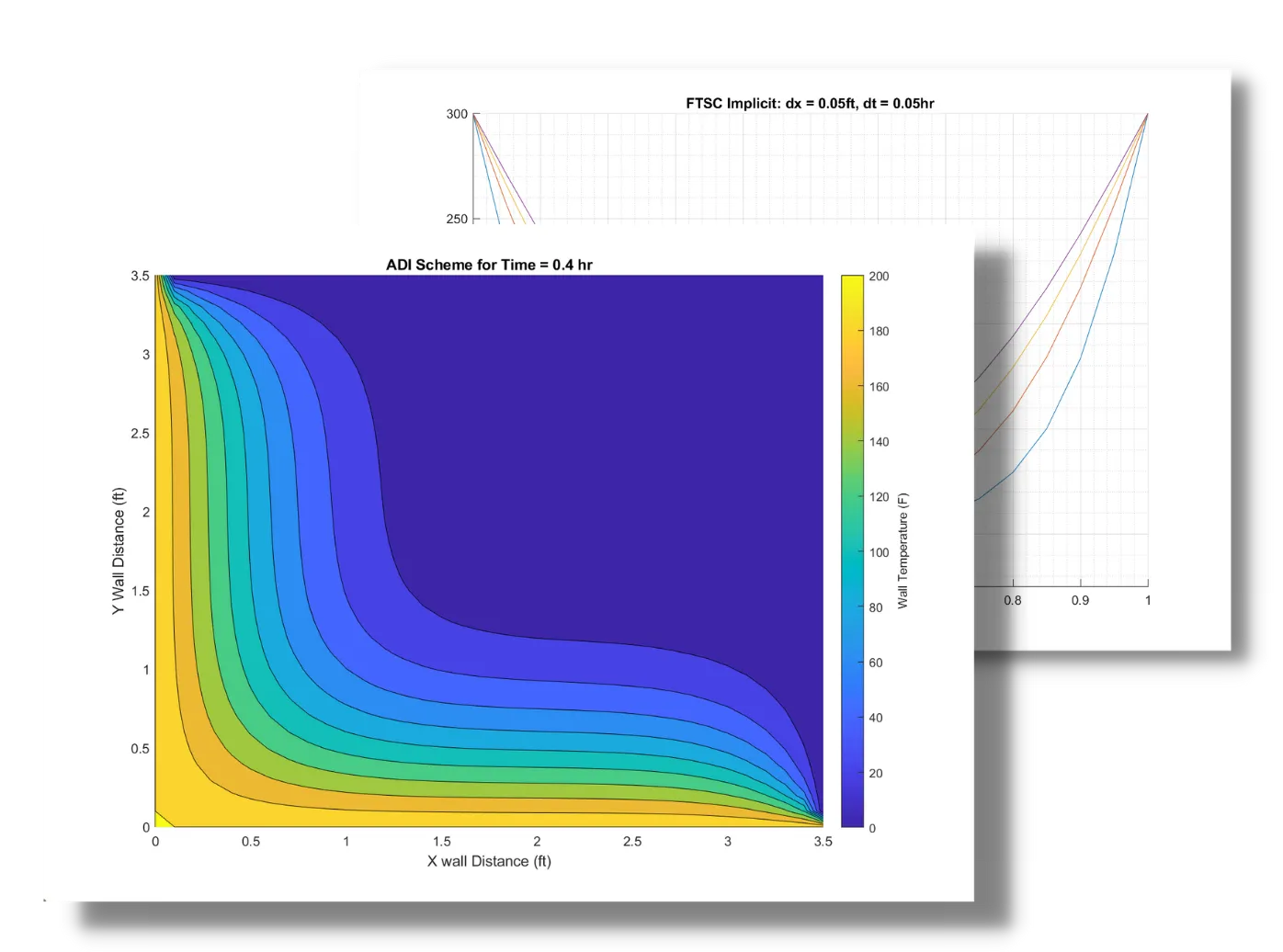

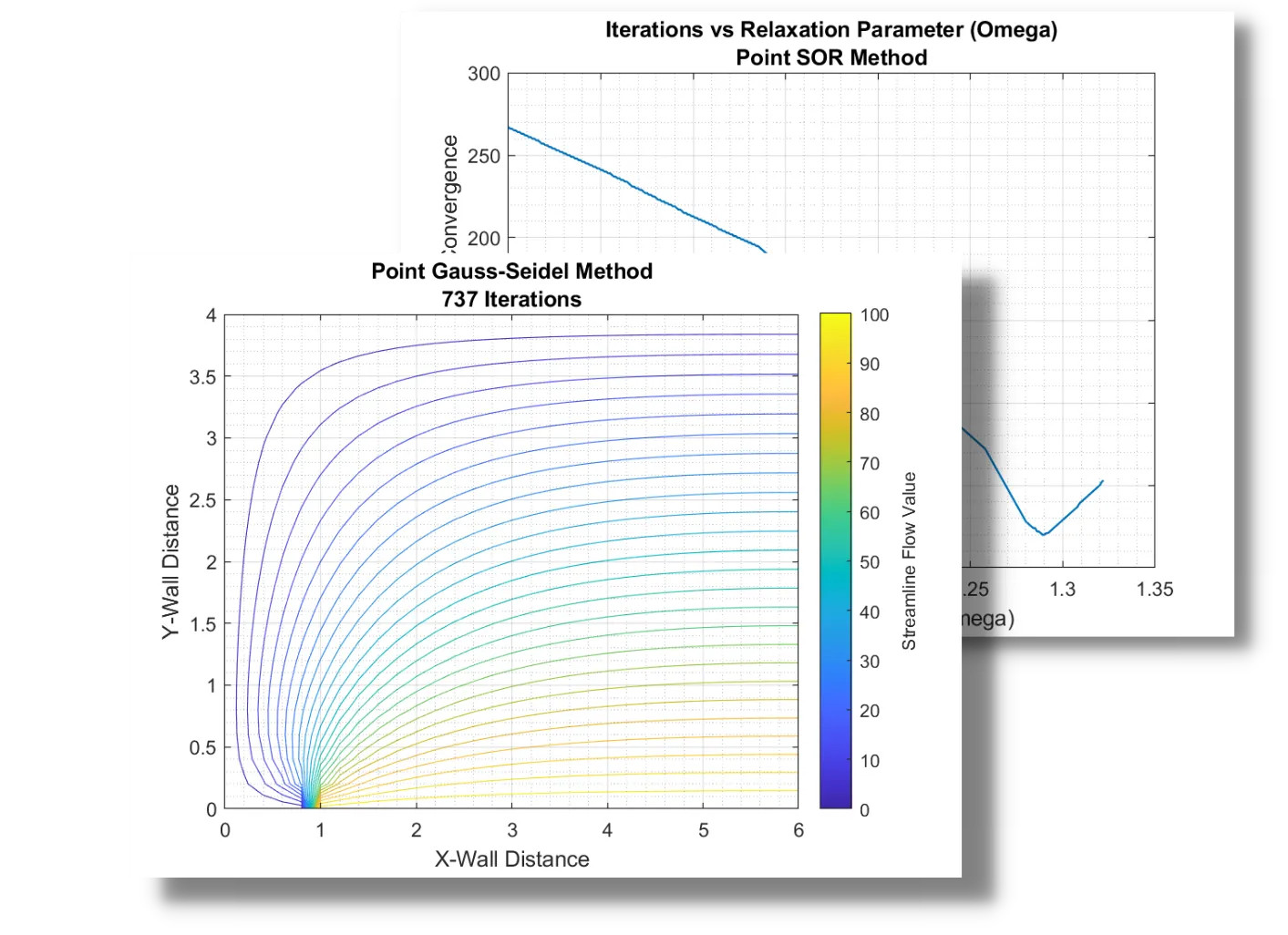

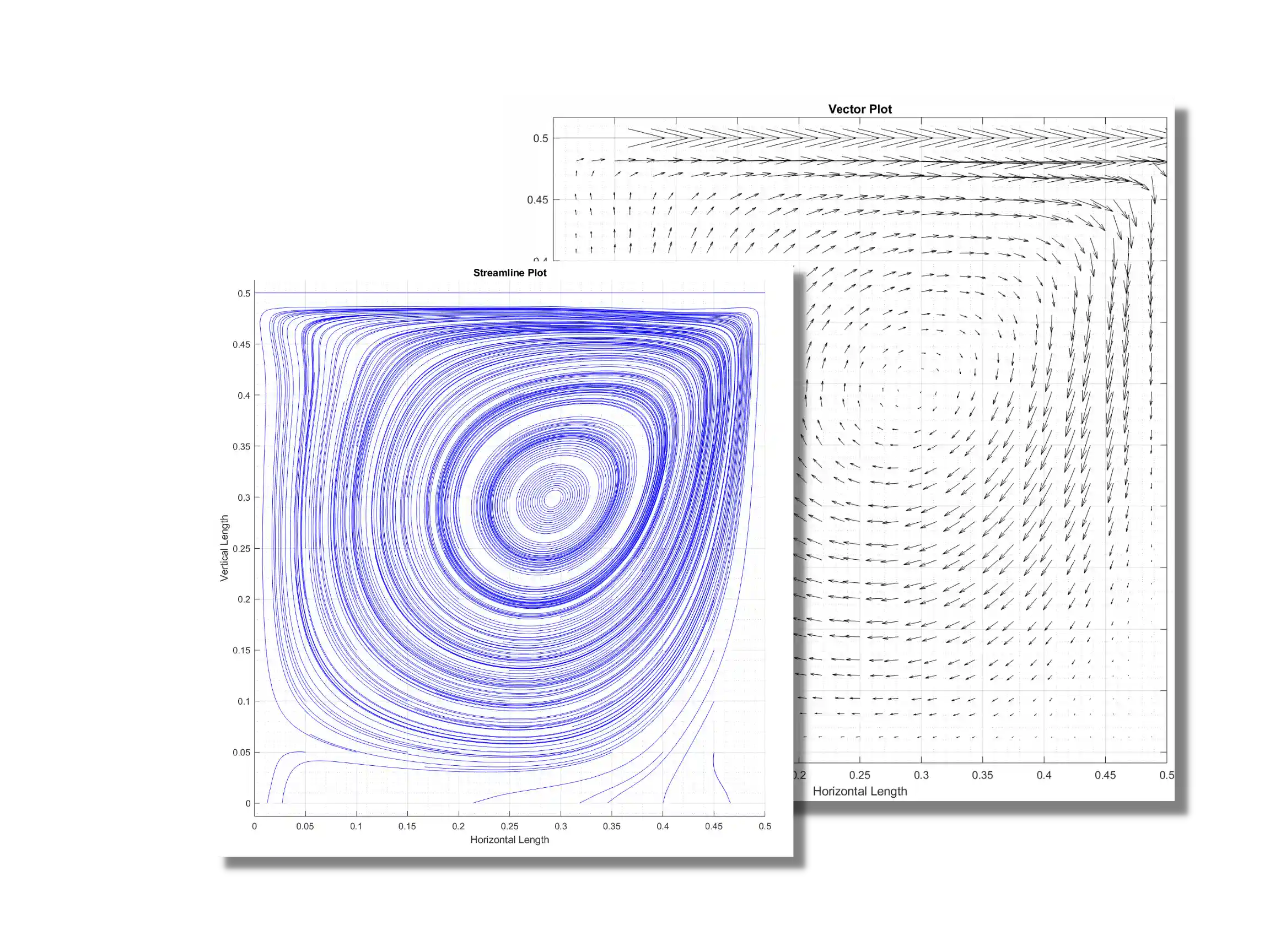

For OCE 5093 : Computational Fluid Dynamics (CFD) For Ocean Eng. at Florida Tech

Tank Diaphragm Analysis

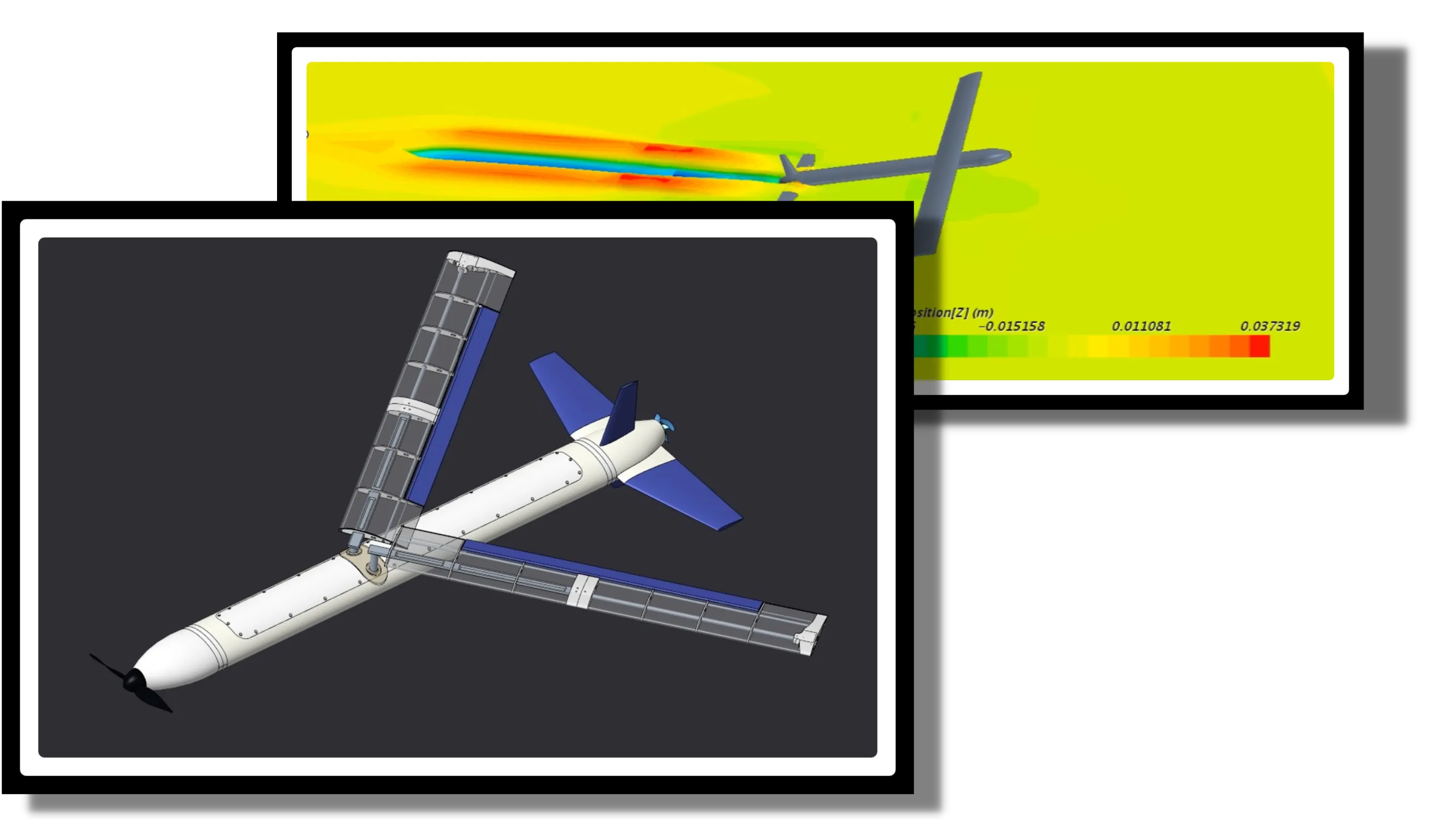

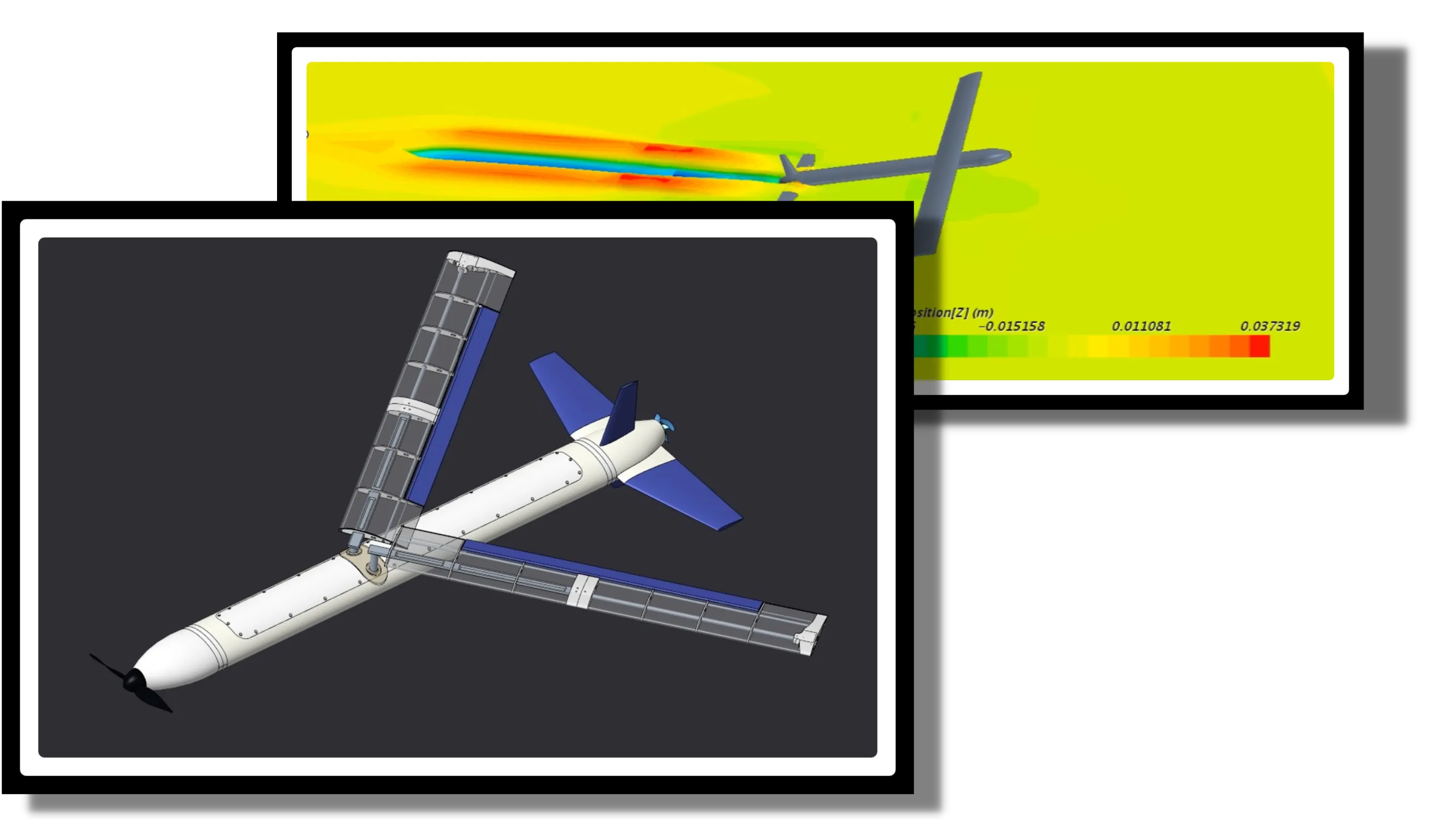

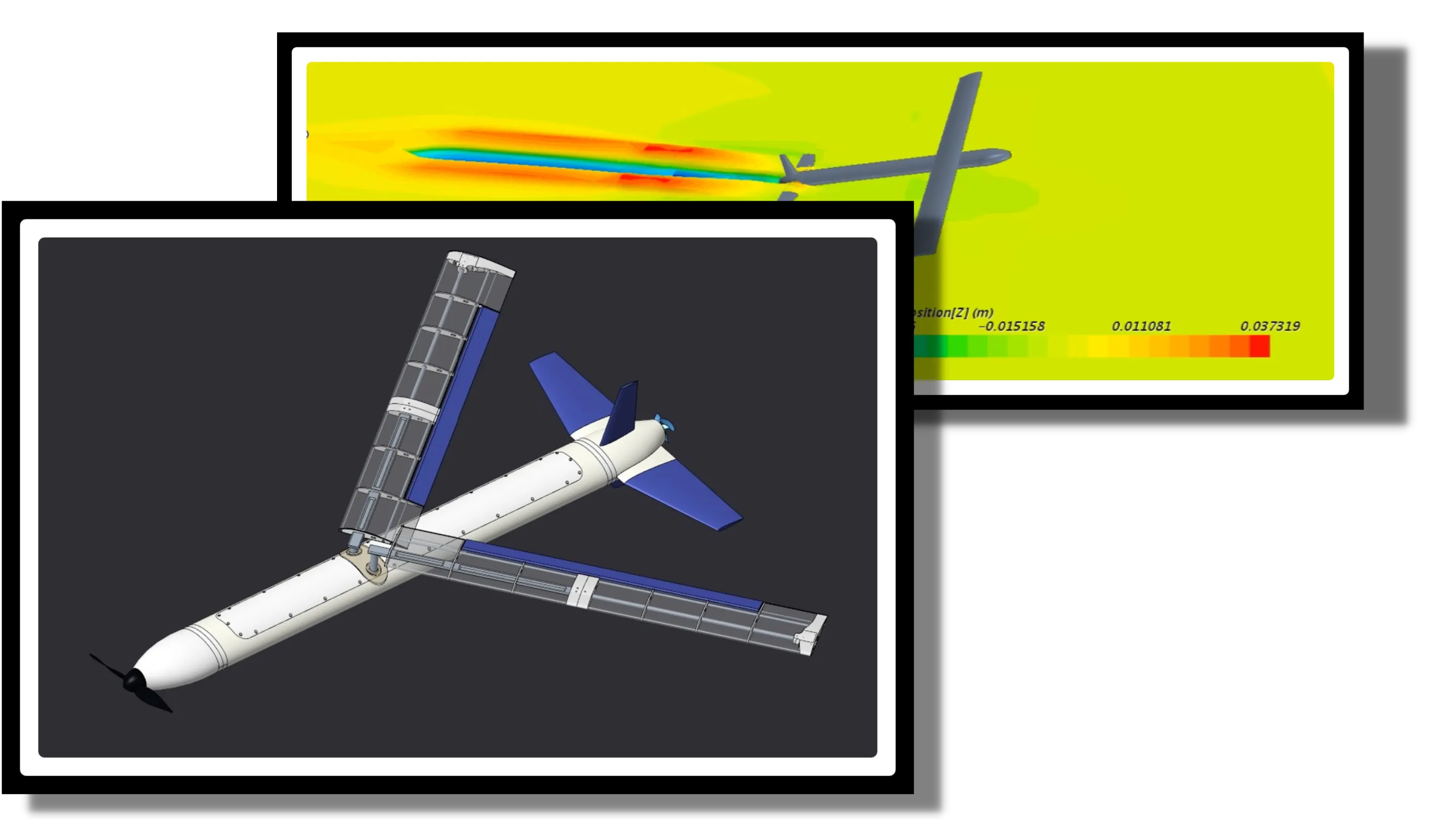

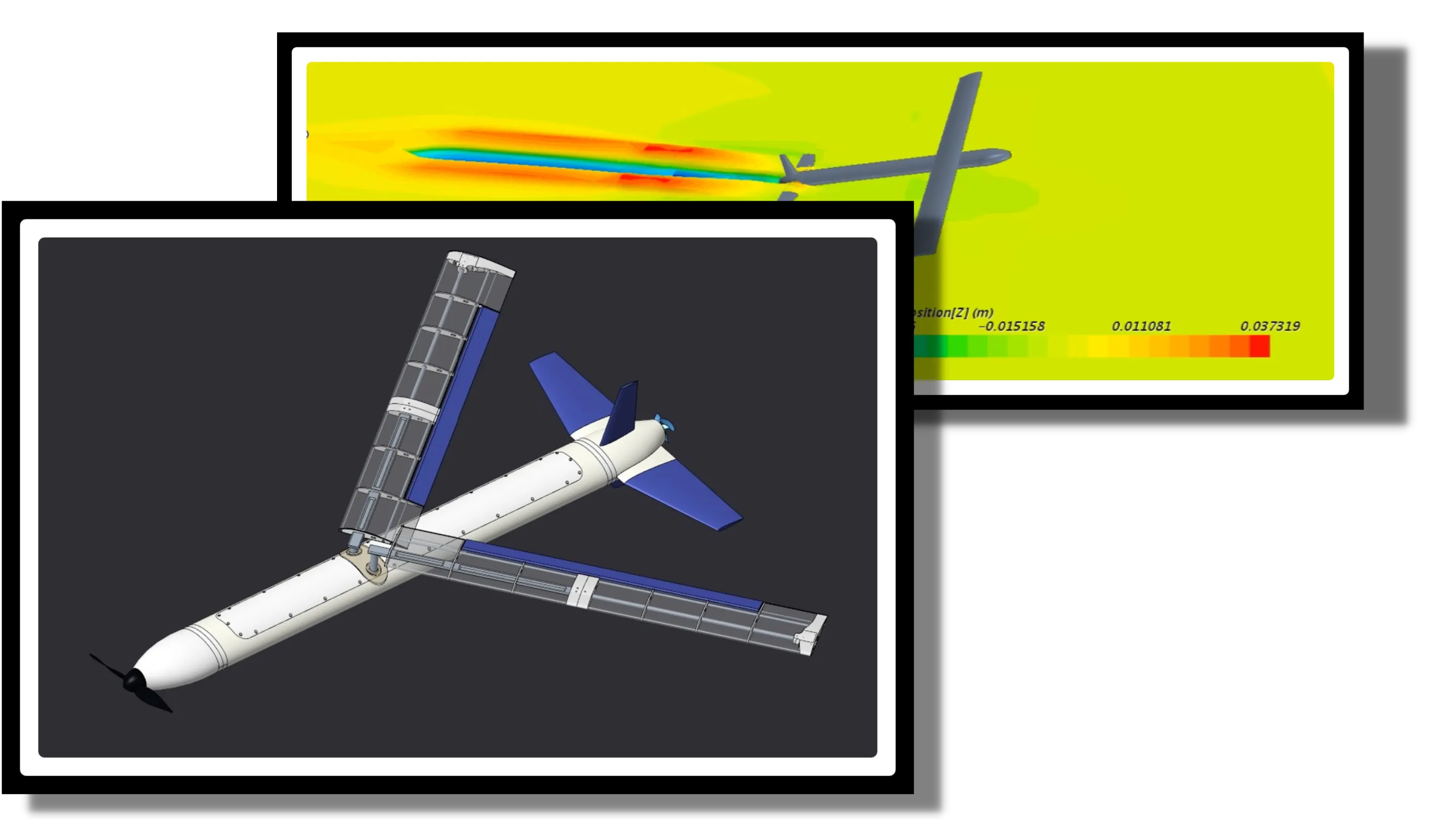

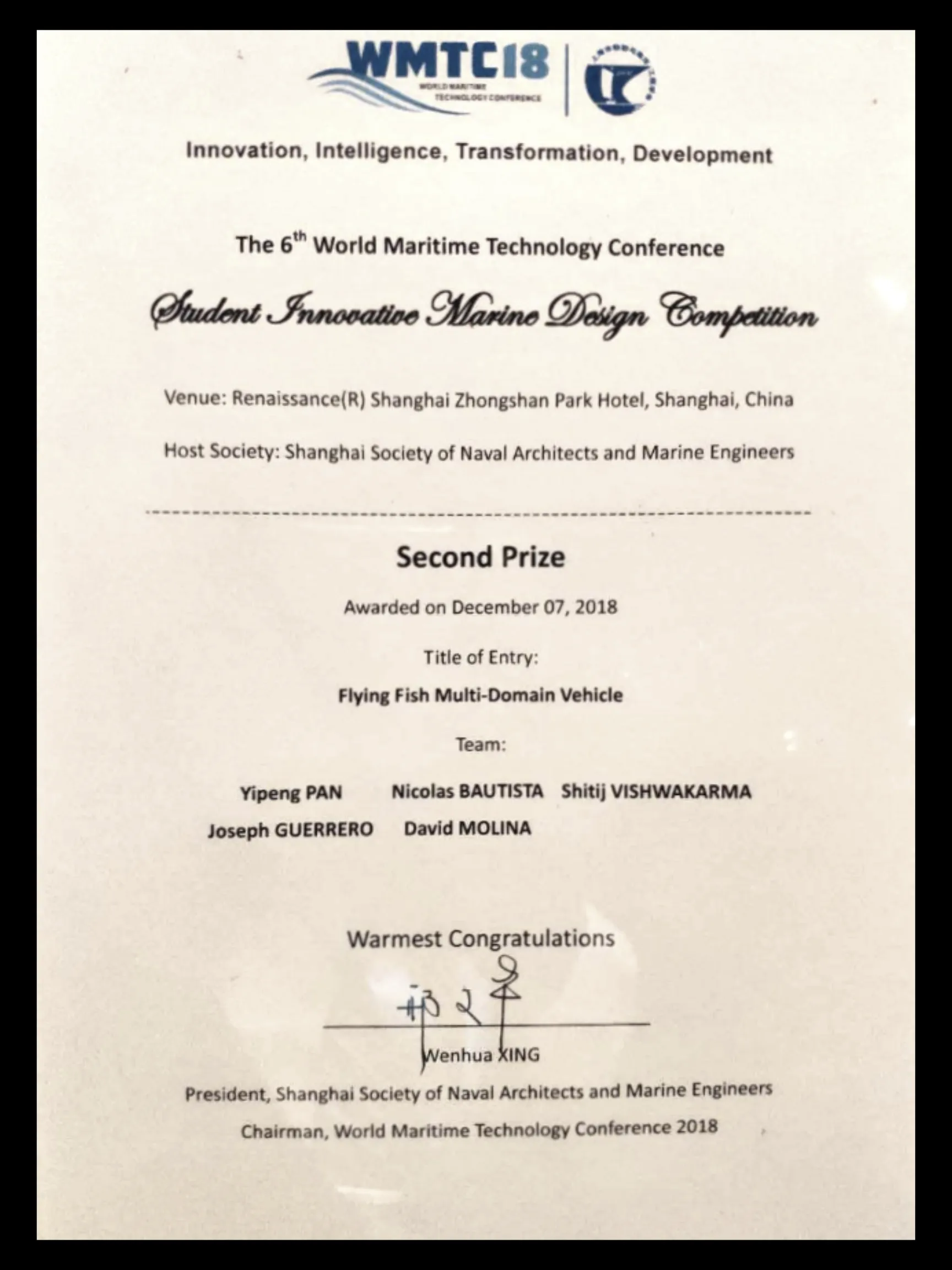

The Flying Fish Amphibious UAV

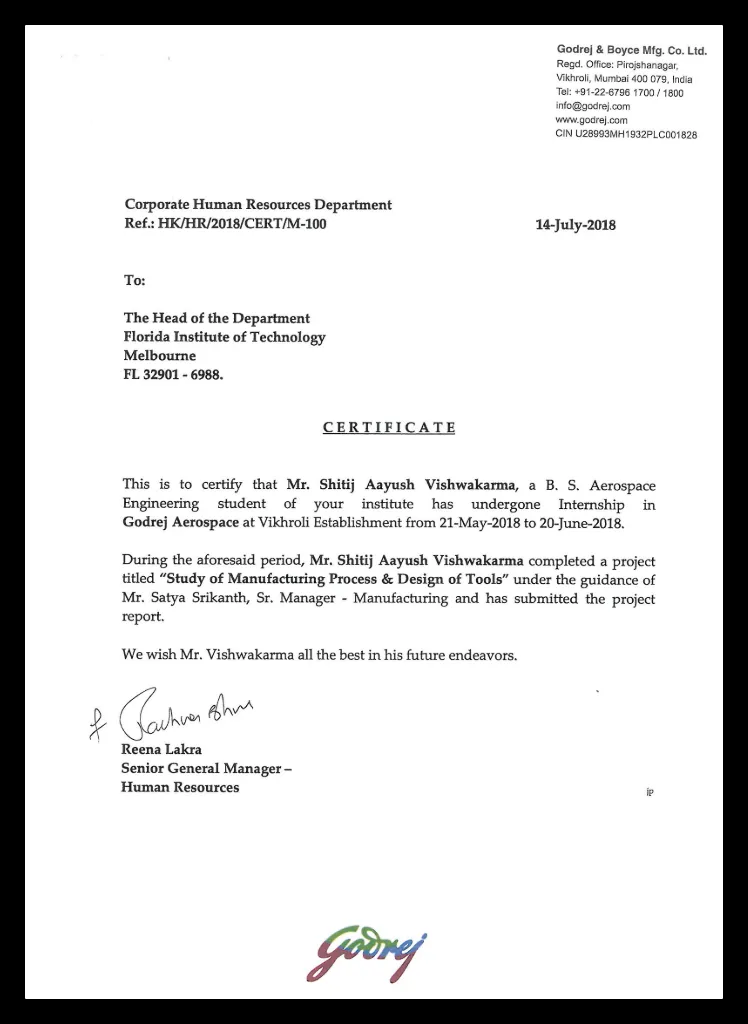

Manufacturing Process & Design of Tools Internship at Godrej & Boyce Mfg. Co. Ltd.

Nautilus Amphibious UAV/AUV

Going into my Master's degree, I wanted to become a well-balanced professional. Hence, while my current area of research is Computational Fluid Flow Analysis, my skill-set includes:

| ANSYS FLUENT | STAR CCM+ | SOLIDWORKS |

| SLA/SLS 3D Printing | PTC CREO | C/C++ |

| MATLAB | FLOW 3D | JIRA |

| HTML | CSS | JavaScript |

These skills and experiences helped me lead the various projects showcased in this portfolio. Lastly, I also owe my success and growth to

Dr. Stephen Wood. I am forever grateful for his support and faith in me.

I can be reached via email or cellphone. Both of which are in my resume, for security & privacy reasons.

I am open to full-time opportunities! If you liked my work, let's discuss how you can benefit from my skills and experience!